Narzędzia

- 5S

Organizacja miejsca pracy - KANBAN Zarządzanie materiałem

- LEAN OFFICE Optymalizacja w biurze

- DESIGN THINKING Sposób myślenia

- LAYOUT Logistyka Wewnętrzna

- SMED Szybkie przezbrojenia

- SOP Standaryzacja pracy

- TPM Total Productive Maintenance

- TWI Training Within Industry

- KPI Visual Management

- VSM Value Stream Mapping

Dowiedz się więcej od ekspertów

Porozmawiaj z Lean Idea

+48 607 86 49 85

KANBAN

System planowania i sterowania przepływem produkcji

KANBAN to słowo pochodzące z języka japońskiego, składające się z dwóch członów: KAN => karta oraz BAN => sygnał. Jest to system planowania i sterowania przepływem produkcji.

Określenie zdolności produkcyjnych maszyny pod kątem ich obciążenia i różnorodności produktów

Analiza czasów przezbrojenia

Ustalenie optymalnej sekwencji produkcji

Zredukuj straty, zyskaj przewagę

Jest wiele metod i narzędzi, które służą planowaniu procesu produkcyjnego. Od prawidłowego zaplanowania tego, co i kiedy oraz przez kogo powinno być zrealizowane zależy powodzenie firmy na rynku i sprostanie wymogom nieustannej konkurencyjności.

Czym jest kanban?

Funkcje KANBAN’u

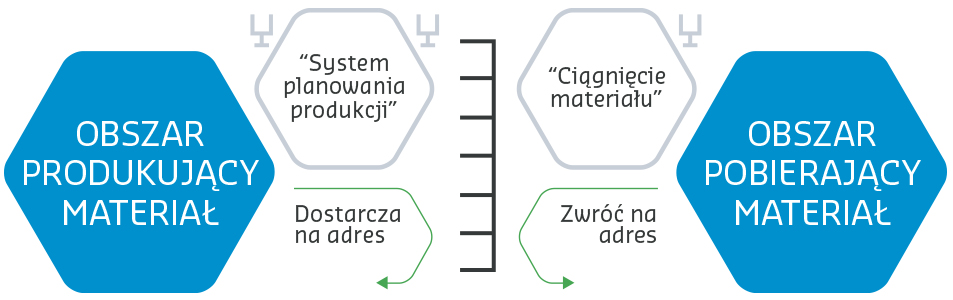

Ciągnięcie materiału – czyli autoryzowane przemieszczenie materiału

Co, kiedy, ile, jak dostarczyć, w jakiej ilości, dokąd dostarczyć, skąd dostarczyć…

System planowania produkcji – czyli autoryzowana produkcja materiału

Ilość produktów, pakowanie, wymagane komponenty, wymagana maszyna/narzędzie…

Karty KANBAN powinny zawierać co najmniej następujące informacje:

- nazwa materiału

- numer artykułu

- miejsce pobrania

- miejsce zdania

- etap produkcji

- liczba sztuk w pojemniku

- rodzaj pojemnika

Korzyści

- kierownicy produkcyjni mają możliwość zabiegać nadprodukcji materiałów pomiędzy poszczególnymi procesami produkcyjnymi

- zapewnia przejrzystość przepływu materiałów

- przyczynia się do redukcji przestrzeni produkcyjnej do niezbędnego minimum

- umożliwia określenie zdolności produkcyjnych maszyn pod kątem ich obciążenia i różnorodności produktów

- pozwala na ustalenie optymalnej sekwencji produkcji.

My jesteśmy dla Ciebie!