praktycznym doświadczeniem

produkcyjne i usługowe

Zobacz jak możemy Ci pomóc

Oferta

Zrealizowane projekty

1256+

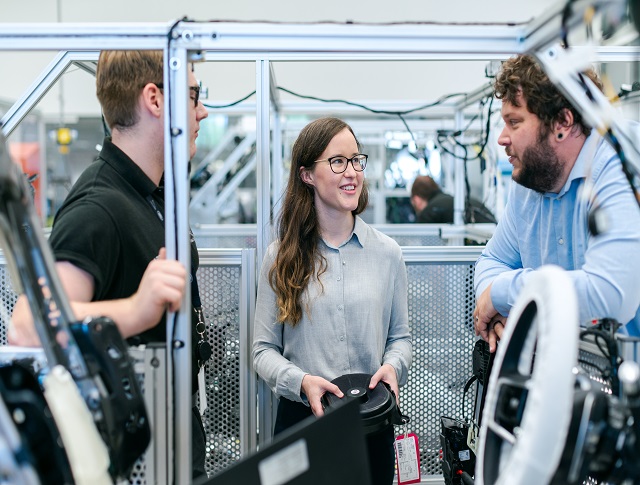

Lean Idea to

idealny partner

dla przedsiębiorstw poszukujących efektywnych i skutecznych rozwiązań oraz optymalizacji swojej działalności. Lean Idea to silny zespół doświadczonych ekspertów.

W ścisłej współpracy z pracownikami oraz w przystępny sposób znajdujemy najprostsze drogi do oszczędności czasu i pieniędzy oraz lepszego wykorzystania zasobów.

W ścisłej współpracy z pracownikami oraz w przystępny sposób znajdujemy najprostsze drogi do oszczędności czasu i pieniędzy oraz lepszego wykorzystania zasobów.

Na rynku od 2009 roku

Na rynku od 2009 roku

- Synergia Rozwiązań

- Holistyczne podejście

- Praktyczne działanie

- Eksperci Praktycy

Lean management

Narzędzia

klienci

Zaufali nam

formularz kontaktowy