Business process mapping – how to start?

Have you ever produced a brilliant idea, but didn’t know where to start to implement it? You may find process mapping useful and it will make organizing your process much easier. If you are planning a new strategy, want to find a way to increase customer satisfaction, or want to know the reasons why certain activities fail, read the article, and find out what process mapping is and how it can make your planning more effective.

Table of contents

- What is process mapping?

- When is it worth to map processes?

- Principles of process mapping

- Process mapping steps

- Types of process maps

- Symbols used in process mapping

- Podsumowanie

1. What is process mapping?

Process mapping is a method of graphically depicting one or more processes and their interrelationships, developed in the early 20th century. It includes not only the activities, operations, dependencies occurring in the organization and the responsibility for each step, but also the instructions, procedures, documentation necessary for the proper execution of operations. It is a practical way to analyze the course of specific processes, which is the first step to further development, improvement, optimization.

Process mapping should depict the actual process and the people realistically responsible for each step. In short, it should be transparent so that it can be a starting point for further process modeling. Mapping is one of the elements of the process approach.

2. When is it worth to map processes?

Process mapping can be extremely useful when you are planning:

- standardization of procedures in a company to introduce a standard by which employees involved in a given process will operate, in order to eliminate the risk of making mistakes, as well as to make employees aware of what exactly belongs to their responsibilities and what are the dependencies between different departments,

- implement a quality management system to see which operations are necessary for a given process and which disrupt the process and which can be abandoned,

- improve the areas where losses or discrepancies in the process have been identified, such as by reducing the execution time of operations or reducing costs, to optimize processes, thus improving the performance of individual departments or even the entire organization. A map of the ideal process should be created, including determining exactly what actions need to be taken to achieve the ideal process.

In addition, when an enterprise is starting up, a new department is being created or a major project is underway, mapping the most important processes can help you find your way around the new situation and understand how to function in it. Mapping is also a good way of communicating with newly hired employees as an alternative to training by an experienced employee with longer tenure in the organization. It is enough to present a new employee with maps of the most important processes to facilitate his or her induction into the workplace, understanding his or her role in the company, the relationship between different areas and responsibilities, without sacrificing a colleague’s time. In addition, process mapping provides a basis for conducting an audit, both internal and external (it will facilitate and greatly accelerate the discussion with the auditor).

3. Principles of process mapping

Process mapping usually uses a top-down method (“from the general to the specific”, top-down), which involves visualizing an overall picture of the company’s operations, then proceeding to clarify selected elements and map individual processes. However, there is a second method – bottom-up. It involves analyzing the activities performed, describing the specific activities of the employees performing a given task and formulating processes based on them. It is more time-consuming, but has greater accuracy.

Once the processes are identified, they should be grouped. They can be divided into management processes (relating to the organization’s mission, goals, strategy, its market position), main processes relating to core business, and auxiliary/support processes relating to the internal customer (procurement, recruitment, etc.).

However, the most important principle of process mapping is that the map should describe the actual, current state, not the desired state. When mapping, therefore, remember not to aim for an ideal process, representing how things should be.

4. Process mapping steps

Step 1: Identify the problem or process to be depicted

First, identify the process you want to map. It could be a new process, a process that is important in terms of the organization’s strategy, a process that has a direct impact on customer satisfaction, a process that you want to improve, or a process with high complexity that causes problems for employees. Then give the process in question a name.

Step 2: Gather the necessary information

It is a good idea to involve all employees involved in the process in order to cover every aspect of the process and accurately delineate all steps. The following information is needed to make a process map:

- the scope of the process, i.e. the beginning and end of the process,

- the most important operations occurring in the process,

- the people responsible for each task (task performers),

- the resources required for the process (input) and the result of the process (output).

Step 3: Determine the order of steps

After gathering information about the process and determining the list of operations necessary for its implementation, arrange them in the right order. The step ends with a picture of the process flow from beginning to end.

Step 4: Draw a process map

Choose a map type and draw the process in question as it stands using process mapping symbols. You can read about process map types and symbols later in this article.

Step 5: Analyze the map to check it for process improvement

Once the process map is done, check it with the employees involved in it and make sure everyone interprets and understands it correctly and agrees on its correctness. Check that no steps were missed during the mapping and there are no inconsistencies.

Once the final version of the process map is determined, when it shows the exact process flow, it can be used for analysis to improve the process. Together with your team, determine if there are bottlenecks or other inefficient areas of the process, which tasks can be skipped, and which can be done better. You can then proceed to implement improvements.

5. Types of process maps

There are diverse types of process maps, all of which share a common goal, but some may work better for a specific process or project. Here are some of the most commonly used maps:

Flowchart

A basic block diagram, or flowchart, is the simplest type of process map. It depicts the successive steps of a process necessary for its execution, as well as the inputs and outputs of the process.

It is useful to use this type of map for planning new projects, modeling and documenting processes, solving process problems, improving team communication, analyzing and managing workflow.

High-level map

Also known as a value chain map, or top-down map. It consists of a representation of the basic activities of a process, a general view of the process. It is limited to the necessary elements of the process, and contains a minimal amount of detail.

A general process map, also known as a top-down map or value chain map, provides a general overview of the process. The steps are limited to the necessary elements of the process, and the map contains minimal detail.

It is used to design and define business processes and identify key required steps and process details. Useful when discussing a process with a person who is not interested in the details, but in the overall process flow.

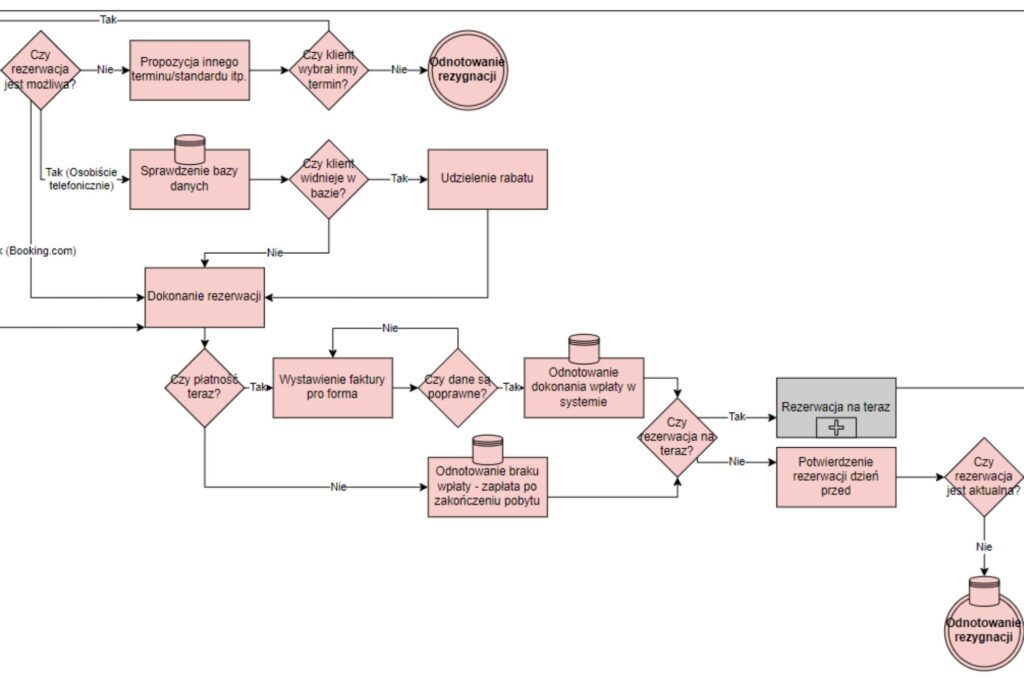

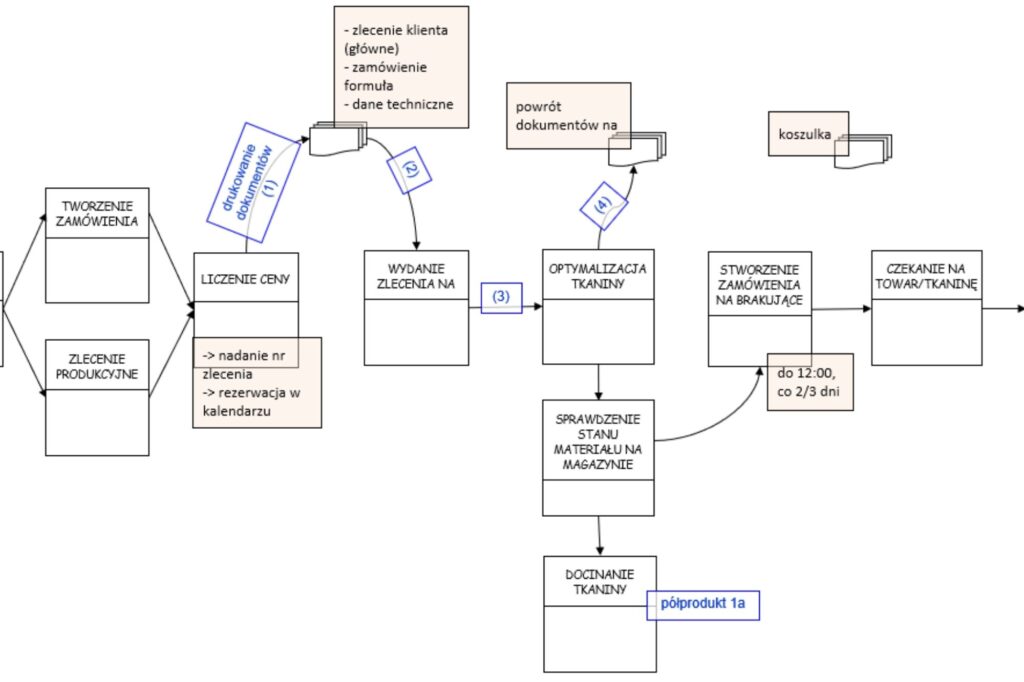

Detailed process map

A detailed process map is a bottom-up map, showing all the details of subsequent steps, as well as sub-processes. It includes inputs, outputs and decision points.

This is the map with the highest level of detail, so it works well when identifying inefficient areas that need improvement.

Flow diagram

Also known as a swimlane map or cross-functional flowchart, it shows the relationships between process steps and the people responsible for those steps. It assigns activities to so-called “swimlane tracks” to designate the people responsible for each task.

It is used to train employees (makes it easier to define roles, responsibilities and interrelationships), as well as to identify potential process errors, e.g. delays, excessive control.

Value stream map

A value stream map shows the flow of materials and information needed to deliver a product or service to a customer.

By documenting data such as cycle times and the number of people involved at each stage, it is useful for identifying areas where resource wastage can be reduced, as well as determining where to focus for future projects to succeed.

SIPOC diagram

SIPOC stands for Suppliers, Inputs, Process, Outputs, Customers. A SIPOC diagram is a chart that defines the key elements of a process and can be used to create a detailed process map. Besides, it can be used to define the scope of complex processes.

6. Symbols used in process mapping

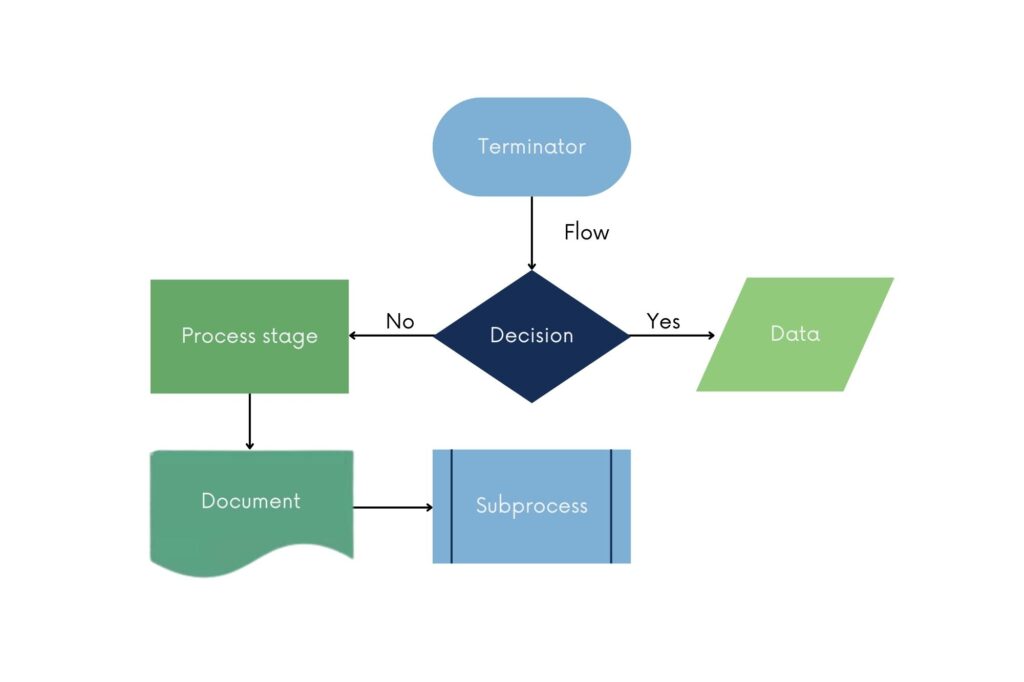

Process mapping uses Unified Modeling Language (UML, for short) symbols. The symbols are intended to represent the most important elements of a process map, including stages, decision points, inputs and outputs.

The most common process mapping symbols are:

- Terminator: ovals marking the beginning and end of a process.

- Process stage: a rectangle representing an activity, a task in a process.

- Flow: arrows connecting process stages and indicating the direction of the process flow.

- Decision: a rhombus representing the point at which a decision must be made, usually with “yes” or “no” options.

- Document: a rectangle with a wavy base representing a document or information to be read.

- Data: a parallelogram specifying the input or output of a process step.

- Subprocess: a rectangle with double vertical lines representing a subprocess.

7. Summary

Process mapping has many advantages, including improving communication among team members, facilitating understanding of the process, helping to identify process flaws and areas that need to implement improvements. It can also be used as training material for new employees.

If you want to learn more about process mapping or have identified an ineffective area in your process, contact us. We will conduct training at your company and help you implement process improvements and eliminate waste.