ZQC Method – How to Prevent Errors

Zero Quality Control (ZQC) is a quality control method aimed at completely eliminating defective products. The term “zero” refers to the goal set by the creators of this method – zero defects in the manufactured products.

This method is based on the principle that the production of defective products can only be prevented by controlling the process in such a way as to prevent the occurrence of defects, even if a machine or operator makes a mistake. It does not focus on finding culprits. Its creators recognized that both people and machines can make mistakes, so the emphasis should be on solutions that prevent such errors from causing defects in the products.

Table of contents

- How does Zero Quality Control facilitate work?

- What are the causes of defective products?

- Four Elements of Zero Quality Control

- Poka-Yoke Systems

- Summary

1. How does Zero Quality Control facilitate work?

In the ZQC system, there is no talk of “preventing errors.” This philosophy assumes that making mistakes is a part of human nature, and people don’t always catch all defects or incorrect equipment behaviours. However, this does not mean that they are unintelligent or negligent in their work.

This method does not involve finding culprits afterward or criticizing employees and admonishing them to “try harder.” Instead, the Zero Quality Control system utilizes solutions that prevent errors or do not allow mistakes to lead to the production of defective products.

Producing only good goods eliminates the need for corrections and facilitates the achievement of overall production plans. It also helps build the company’s reputation, maintain high product quality, and reduce costs. Furthermore, a company’s strong position undoubtedly affects job security and the quality of work.

Employees involved in production and assembly play a significant role in achieving the goal of eliminating defective products.

2. What are the causes of defective products?

Defective products typically arise in most cases due to one of the following five situations:

- Inadequate procedures or standards are established during the process planning. For example, incorrect temperature settings during heat treatment can lead to defects. Proper planning can prevent such situations.

- Irregularities occur during the execution of operations. An example is excessive play in a machine bearing, which can result in defects. This can be avoided with proper machine maintenance.

- The use of damaged or non-standard materials. Quality control of supplied materials and their compliance with standards is the solution to this problem.

- Wear and tear of machine components (e.g., bearings or tools) can lead to defects. Diligent machine maintenance and proper tool management can help prevent such issues.

- Finally, even if none of the four situations above occur, the production of defective products can be caused by simple human errors or inaccuracies in performing operations.

The first four of the situations described above can be anticipated, and solutions can be implemented to eliminate the sources of defects. However, common errors – which are the most frequent cause of defects – occur unexpectedly. This is what makes them much harder to prevent.

Since the goal of Zero Quality Control is the complete elimination of defective products, rather than just reducing their number, this system includes ways to detect errors before they lead to defects. This is achieved through control functions that provide the necessary conditions for producing good products.

Below is a detailed description of two control techniques used in the ZQC system.

1.Traditional Quality Improvement System

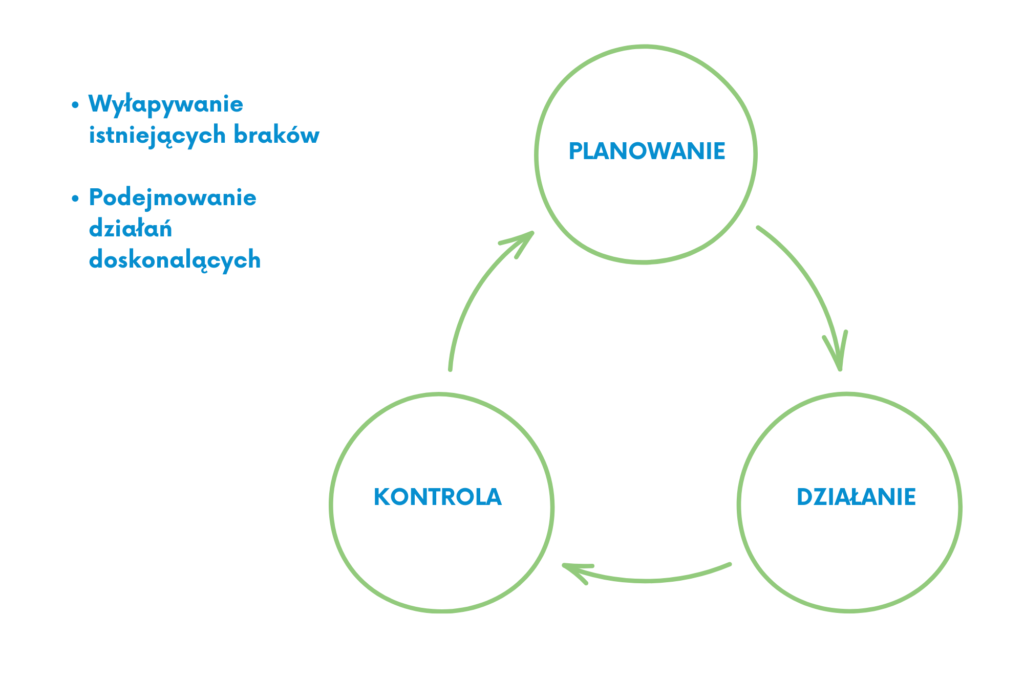

Very often, the basis of traditional quality improvement systems is the “plan, do, check” cycle, which is illustrated in the diagram below.

In this cycle, optimal process conditions are established during the planning stage. Then, based on the plans, specific actions are taken, and finally, in the control phase, the quality of the products is checked. In case of discovering defects, the controllers provide feedback to the planning department, where corrective actions are taken as part of the next cycle to improve process conditions.

It is widely believed that continuous repetition of functions in this cycle leads to an improvement in product quality. However, in reality, this cycle never fully prevents the production of defective products, especially those caused by human errors or incorrect machine operations. The plan, do, check cycle does not provide the capability to catch errors but only offers feedback about the existence of defective products.

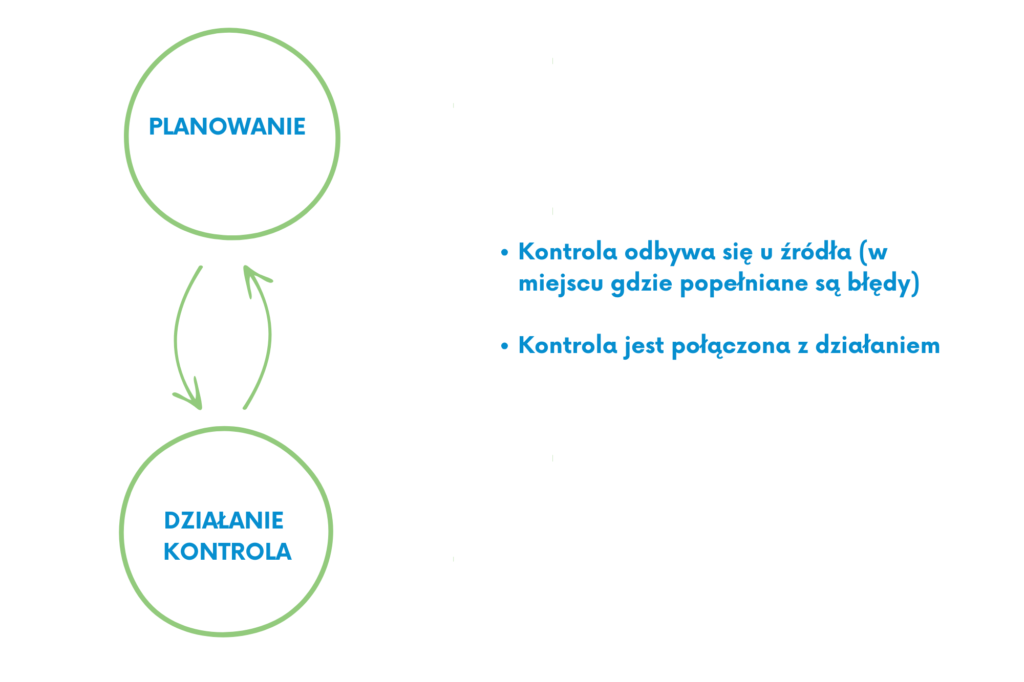

It’s important to remember that an error and a defect are not the same. An error is often the cause of defective products. Therefore, instead of catching defective products (which have already been produced), the focus should be on discovering what errors led to their creation. Zero Quality Control addresses this issue by combining the action and control stages into one, allowing for proper plan execution.

2. Combining the Action and Control Stages in the Zero Quality Control System

This concept assumes that unforeseen errors can occur between the planning and action stages. Something might happen there that prevents the plans from being properly executed. That’s why in this system, the action and control phases are combined so that the control takes place at the same location where problems can arise. When a supervisor or worker discovers an error – such as incorrect operating conditions – they can rectify it before completing the task.

The combination of the action and control stages is referred to as source control – checking the process conditions before starting the operation. This allows for immediate feedback and problem resolution before defective products occur, rather than after they have been produced.

The Zero Quality Control method consists of four fundamental elements – source control, 100% inspection, quick feedback, and error prevention systems called Poka-Yoke. In the later part of the article, these elements will be discussed in more detail.

3. Four Elements of Zero Quality Control

This system prevents the production of defective products because it integrates the control and action stages into one, which is part of the quality improvement cycle. ZQC owes its effectiveness to the utilization of four fundamental elements:

- Implementing source control, which allows for catching errors before they lead to defects.

- Utilizing the 100% inspection method, which involves inspecting all products rather than just selected samples.

- Providing immediate feedback, enabling prompt corrective actions.

- Using Poka-Yoke devices installed on production or assembly equipment, serving control and support functions, as everyone makes mistakes.

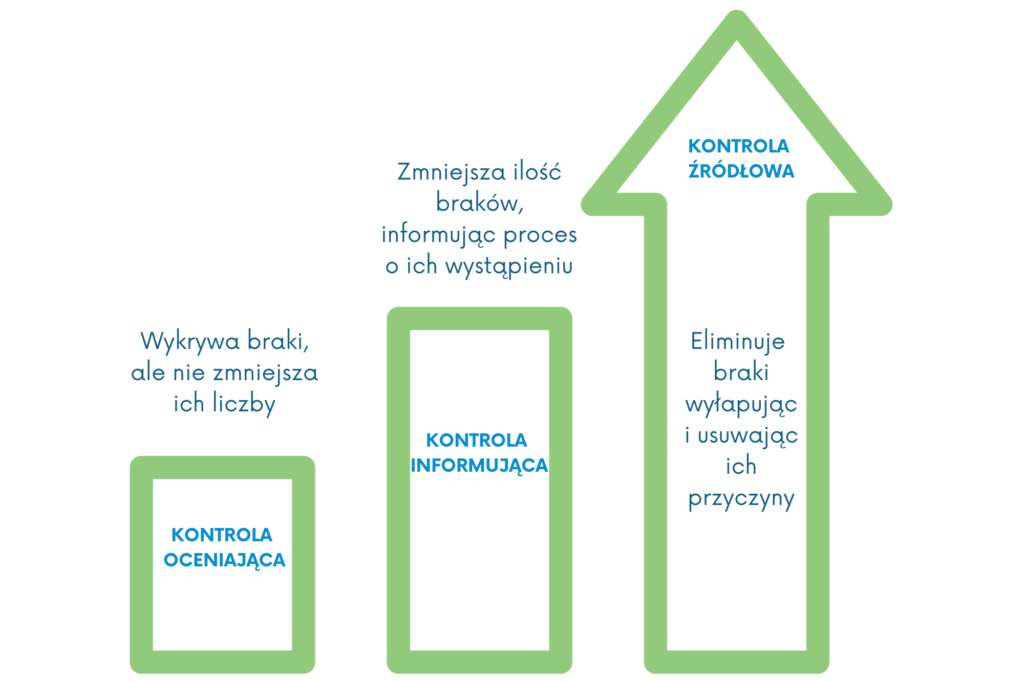

Source control, which is the first of these elements, is a key control function in the Zero Quality Control system. It allows for ensuring proper process conditions even before its commencement. However, source control differs from other types of control that are commonly known, such as evaluating or informing. Examining traditional types of control will help better understand the essence of source control, which includes:

- Control that detects defective products – Evaluating Control

- Control that leads to a reduction in the number of defective products – Informing Control

- Control that leads to the complete elimination of defective products – Source Control.

In quality control programs, most companies use the first two types of control, so they can be considered traditional methods. However, only source control truly allows for the elimination of defective products. Understanding the essence of each type of control, as well as knowing the full potential they offer, is extremely important.

• Evaluating Control – allows for the detection of defective products but does not prevent the occurrence of defects and • does not provide quick feedback to halt the process before producing more defects.

• Informing Control – helps reduce the number of defective products by providing feedback to workers in the process where defective products are being produced. Its primary aspect is to notify these workers of the problem as quickly as possible so they can correct it. However, it does not enable the complete elimination of defective products. There are three main types of informing control: statistical quality control, in-process control, and self-control of products in the process.

• 100% Inspection – allows for catching all errors by inspecting all manufactured products, not just statistical samples.

• Quick Feedback – signifies a faster problem resolution. It enables the immediate correction of errors, rather than waiting until a large number of defects accumulate or conditions change, making it impossible to draw proper conclusions.

• Poka-Yoke Systems – detect errors that we may not notice. They are installed on machines to continuously perform source control and provide real-time feedback to operators.

4. Poka-Yoke Systems

In these systems, sensors or other devices are used, which are installed on machines to detect errors that may escape the operator’s attention. They are essential for the proper functioning of two key elements of ZQC – 100% inspection and quick feedback and corrective actions.

True implementation of Zero Quality Control means utilizing Poka-Yoke systems during source control to catch errors before they result in defective products.

They can also be used in informing control, which occurs immediately after the process is completed. This may not eliminate all defects, but it can prevent the transmission of defective products to further processes on the production line.

Poka-Yoke systems allow for regulating the production process and preventing defective products through the use of two types of solutions:

- Control System: which stops the equipment when abnormalities occur or

- Warning System: which signals to the operator the need to address the issue.

The control system is significantly more effective as a Zero Quality Control tool because its actions do not depend on the employee

The three main methods for using Poka-Yoke systems are:

- Contact Methods: These methods rely on Poka-Yoke solutions that remain in physical contact with the product. They are often used for parts or products with irregular shapes.

- Constant Value Methods: Devices using this method count how many times something has been done. When the required count is reached, the system signals it or prevents further processing.

- Motion/Stage Methods: These are employed when it’s crucial for a specific motion or stage of the process to be completed within a set time, such as during a machine cycle.

5. Summary

The creator of Zero Quality Control, Shigeo Shingo, believed that making mistakes and forgetting are inherent aspects of human nature, for which people should not be blamed. That’s why he developed the solution to this problem, known as Zero Quality Control.

Zero Quality Control is more than just a few operating techniques. It is a fundamental concept for the complete elimination of errors in production. It focuses on improving production conditions rather than finding culprits for mistakes that have been made.